rockwell hardness test experiment conclusion|rockwell hardness testing guide pdf : bespoke The hardness number is directly obtained in the experiment. The Rockwell hardness is derived from the measurement of the depth of the impression EP = Depth of .

Resultado da 18 de enero 2023 a las 13:39 hrs. Babo es una de las tendencias más virales en los últimos días. Tras filtrarse un video explícito que subió a su cuenta .

{plog:ftitle_list}

Jujutsu Kaisen (呪術廻戦, rgh. "Sorcery Battle") is a Japanese manga series written and illustrated by Gege Akutami. It has been serialized in Shueisha's shōnen manga magazine Weekly Shōnen Jump since March 2018, with its chapters collected and published in 25 tankōbon volumes as of January 2024 . The story follows high school student Yuji Itadori as he joins a secret organizati.

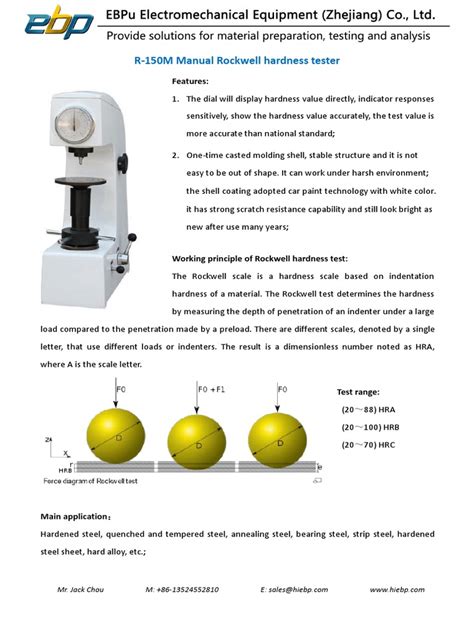

rockwell hardness testing instructions

Rockwell hardness test is developed by the Wilson instrument co U.S in 1920. This test is an indentation test used for smaller specimens and harder material. This hardness test is preferred because it is simple, easy and relatively nondestructive. Objective: Determine the Rockwell .CONCLUSION For this lab hardness is defined as the resistance to indentation .

CONCLUSION For this lab hardness is defined as the resistance to indentation under and applied load corresponding to the deformation of material under applied load. We performed the indentation test to test the hardness of a metal .

Auto Abbe refractometer services

In conclusion, the Rockwell hardness test serves as an indispensable tool for engineers, researchers, and manufacturers seeking to understand and characterize the mechanical .1. AIM: To determine the Rockwell Hardness of a given test specimen II. APPARATUS: Rockwell Hardness testing machine, Test specimen. III. THEORY: HARDNESS- It is defined as the . The hardness number is directly obtained in the experiment. The Rockwell hardness is derived from the measurement of the depth of the impression EP = Depth of .Based on the method of measurement, conventional hardness testing are of three types, namely Scratch Hardness (resistance to scratching or abrasion), Rebound Hardness (energy absorption under impact loading) and the most .

Rockwell hardness tester presents direct reading of hardness number on a dial provided with the machine. Principally this testing is similar to brinell hardness testing. It differs only in diameter and material of the indenter and the applied .The Rockwell hardness test measures hardness by pressing an indenter into the material surface under a speci c load and then measuring the depth of penetration. Other tests like .

Objective. The main objective of this experiment is to introduce two important basic mechanical property tests; hardness (using Rockwell testing) and impact (using Charpy testing).The Rockwell hardness test is performed by applying a minor preload to an indenter on the material surface, then applying a major test load. The indenter depth is measured after removing the major load. The difference in depth .

This study investigates the effects of hardening and physical factors on Al 2024 Alloy's hardness by the application of Rockwell hardness test. Its main goal is understanding the concept of hardness and examining different properties .Rockwell Hardness Test; The Rockwell test differs from the Brinell and Vickers tests is not obtaining a value for the hardness in terms of an indentation but using the depth of indentation, this depth being directly indicated by a pointer on a . Even though the indent impression is comparatively small when compared to the Brinell Hardness Test. The Rockwell hardness number (Rhn) must be specified with the scale name as prefix all the times. Precautions in . View conclusion exp 8.docx from FKKSA BKF1751 at University of Malaysia Pahang. CONCLUSION AND RECOMMENDATION From the experiment, the hardness testing is to measure of hardness of materials. AI Chat with PDF. . Therefore, we should learn to measure the hardness accurately. Rockwell hardness testing process is most simple and .

hardness of the aluminum coupons decreased slightly when heated for 20 minutes, and slightly more when heated for 40 minutes. Bad Conclusion 2: This lab experiment consisted of students observing and understanding the usage of Rockwell hardness testing machine to help determine hardness of cold worked samples.Applications of Rockwell Hardness Test. Quality Control: Commonly applied in industries that require hard materials on parts and other manufactured products. Material Selection: This tool supports the process of identifying materials that will be applicable depending on the hardness needed. Heat Treatment Evaluation: Using the assessment of the hardness of the treated .

In conclusion, the Rockwell hardness test serves as an indispensable tool for engineers, researchers, and . aerospace, and maintenance to assess hardness without the need to transport samples to a lab. Working principle- The Rockwell hardness test is a widely used method to measure the hardness of materials, particularly

The main objective of this experiment is to introduce two important basic mechanical property tests; hardness (using Rockwell testing) and impact (using Charpy testing). Chauvenet’s Criterion will be applied to identify . For Rockwell hardness testing, no optical measurements are required; all readings are direct.

VICKERS HARDNESS TEST: The Vickers hardness test uses a square base diamond pyramid as the indenter. The included angle between the opposite faces of the pyramid is l36°. The Vickers hardness tester operates on the same basic principle as the Brinell tester, the numbers being expressed in the terms of load and area of the impression.Conclusion. The Rockwell hardness test is widely used to standardize the hardness of metals. Although it is possible and easy to perform, it can be time-consuming and expensive. It is also important to note that since the hardness of a material is determined by the Rockwell Hardness number, it doesn’t indicate whether the material with that .3.1 Macro Hardness Test Methods 3.1.1 Rockwell Hardness Test The Rockwell hardness test method consists of indenting the test material with a diamond cone or hardened steel ball indenter. The indenter is forced into the test material under a preliminary minor load 𝐹0 (Fig. 1A) usually 10 kgf. When equilibrium has been reached, anRockwell hardness test is one of the static hardness testing methods using indentation depth as a measuring criterion. Basically, two types of indenter are used; one Diamond spheroconical (Brale) indenter with an angle of 120 O and a spherical tip of 0; second is steel ball indenter with diameters as 1/16, 1/8, 1/4, ½ inches.

The Rockwell hardness test is a indentation hardness test in which a diamond cone having an included angle of 120o and radius of curvature at the tip of 0.2mm, or a hardened steel or hard metal ball having a diameter of 1.5875mm for B, F, G and all 'T' scales or 3.175 mm for E, H and K scales are used.The indenter is forced into the surface of a test piece in two steps, initially a . ASTM E10: This standard covers Brinell hardness testing in metallic samples. ASTM E18: This standard includes the various ways that Rockwell hardness can be measured by standard methods, specifically for metallic materials. ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness .The Rockwell hardness test method, as properly defined in ASTM E-18 standards, is the most commonly used hardness test method among all the other methods. . Conclusion. To wrap, Rockwell hardness testing is very .

Infinita Lab leads the way in material science, offering a wide selection of over 2,000 tests across various industries, including the widely recognized Rockwell hardness test. This essential evaluation, pivotal for determining material hardness, particularly in metals, examines the depth of penetration by an indenter under different loads.Hardness Test 1/5 LAB 2 HARDNESS TEST OBJECTIVES (1) Make Brinell, Vickers and Rockwell hardness measurements on different materials specimens. (2) Compare the measurements in hardness with each other. INTRODUCTION Hardness can be defined as resistance to penetration, resistance to abrasion, resistance

Rockwell hardness test is one of the static hardness testing methods using indentation depth as a measuring criterion. Basically, two types of indenter are used; one Diamond . The experiment also showed how the hardness of the sample was dependent on the cooling rate. With an increase in the cooling rate, the sample was found to have a . Diagram of Brinell Hardness Testing Machine. Brinell Hardness Test is one of the most important hardness tests in the engineering industry and metallurgy. It is used when the surface of the metal is very rough to use another hardness test on it. There are two methods to perform the Brinell hardness Test on the metal as follows: Standard Method .

What conclusions might you draw about the possible effects of indents on the mechanical properties of indented components? . Figure 2 - Schematic Diagram of Rockwell Hardness Test. LABORATORY REPORT 1. Include the following information in the laboratory report. 6061-T6 aluminum 1018 (HR) or A36 steel This experiment was carried out in our university lab to determine hardness of metallic materials using Rockwell Hardness test Discover the world's research 25+ million members

Rockwell testing falls into two categories: Regular Rockwell testing (e.g., C and B scales) and Rockwell superficial testing (e.g., 30 N and 30 T scales). High Rockwell hardness numbers represent hard materials and low numbers soft materials. d 2 www.wilsoninstruments.com Fundamentals of Rockwell Hardness Testing

See also: Hardness. Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload .A number of factors influence hardness tests results. As a general rule, the lower the load you use in the hardness test, the more factors that need to be controlled to ensure an accurate conclusion of the hardness test. Here are a few of the most important factors to consider to ensure an accurate conclusion from a hardness test.The Rockwell hardness test is applied globally for the application of an experimental indentation hardness test. The Rockwell test is a quick process, very cost-effective, and non-destructive test (causing only minor indentation on the specimen material). The Rockwell hardness test is a simple process that is why it can be performed by anyone .An indentation process, Rockwell Hardness testing is straightforward and uncomplicated in practice. Using a diamond cone or sphere-shaped indenter, a minor load is applied to a sample of the investigated material to remove any surface effects. . A multi-discipline laboratory, our Metallurgy Testing lab offers professional support that .

Thermostat Auto Abbe refractometer services

Rockwell Hardness Test (Before Cold Working) *Using type B Scale (red) Force (kg) 100 Thickness (mm) 1. Hardness 1 98 Hardness 2 94 Hardness 3 95 Hardness 4 92. . CONCLUSION For this lab hardness is defined as the resistance to indentation under and applied load corresponding to the deformation of material under applied load. We performed .

Resultado da AfterShock Frenzy is a classic slot that has 3 reels and 5 pay lines which feature the well known 7s and Bar symbols amongst many others.

rockwell hardness test experiment conclusion|rockwell hardness testing guide pdf